From THE GALAXY OF STRATS book

Interviewer: Yasuhiko Iwanade

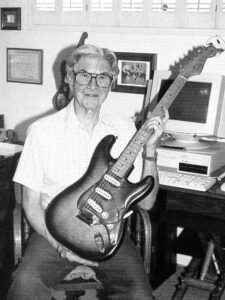

KARL OLMSTED

“I believe that it was because we faithfully responded to Leo’s requests that we were able to accomplish a high level of work that we can be proud of for the rest of our lives.”

Karl Olmsted, who worked alongside Lyman Race at Race & Olmsted Company from the early 1950s, supplied the molds, machinery, and parts necessary for guitar production for Leo Fender. While he had never been in the spotlight as a staff member supporting Leo, his words vividly depict the process of creating the Stratocaster down to the finest details.

Q: How did you come to work with Leo Fender?

A: At that time, we were working for an aviation-related company in Orange County (the area that includes Fullerton and Anaheim), but we wanted to do something independent. That’s when Leo approached us. Our workshop was right behind the Fender factory, and Leo took great care of us. So, we worked hard to meet his expectations. However, it’s also true that he was a very demanding person. He never compromised and didn’t accept the word “impossible.” No matter how much we said, “That can’t be done,” it wasn’t acceptable. He would say, “Find a way to make it work. That’s your job.” It was tough to keep up with him.

Q: Could you provide more specific details about the nature of the work, such as the molds for the body?

A: The body molds were made of a quarter-inch iron plate which we called a template. We traced the shape from the blueprints and cut the iron plate to create it.

Q: Were similar templates used for the Stratocaster as well?

A: Yes, they were. However, the Stratocaster had an additional cavity that was one step deeper in the control area, and there was also a cavity on the back of the body for the springs. I believe we used two templates combined. The size was the same as the body, and we used a woodworking machine called an overhead pin router to cut them. The table had guide pins, against which we aligned the edge of the template for processing.

Q: Did you cut the body, for example?

A: Of course. We had to check if the molds we made were usable.

Q: What about prototypes?

A: It is common to have prototypes for parts and such to ensure proper fit and functionality. We certainly made prototypes as well.

Q: Is it safe to say that the guitar you currently have (referencing the photo) was used for a similar purpose?

A: This one was given to us by Leo in 1954 and was used to check the fit of the parts, among other things. Even after the product was completed, whenever there were improvements or specification changes, it was necessary to check if those parts fit properly with the other components. That’s why it’s always necessary to have an actual instrument at hand.

Q: The tremolo on the Stratocaster is an excellent design, but how was it developed?

A: We struggled with that. The initial prototype was supposed to be okay, but it was scrapped abruptly because it lacked sustain. Although we had already made the molds and partially produced the parts, Leo completely gave up on it and started developing a new type. After a while, he came up with the idea of attaching an iron block to the bridge section, which beautifully solved the problem.

Q: Are there any other memorable aspects related to the Stratocaster?

A: As for the parts, I remember the three-dimensional plate around the jack very well. It required deep pressing, so we had some difficulty choosing the material. I recall using a soft brass material.

Q: So, you were involved in every part of the Stratocaster. Finally, could you say a few words?

A: Leo Fender was a demanding person, and we had a tough time keeping up with him. But when I think about it, it was because we faithfully responded to his requests that we were able to accomplish work at such a high level that we can be proud of for the rest of our lives. I am filled with gratitude toward Leo, who brought out our maximum abilities.